Technological Challenge

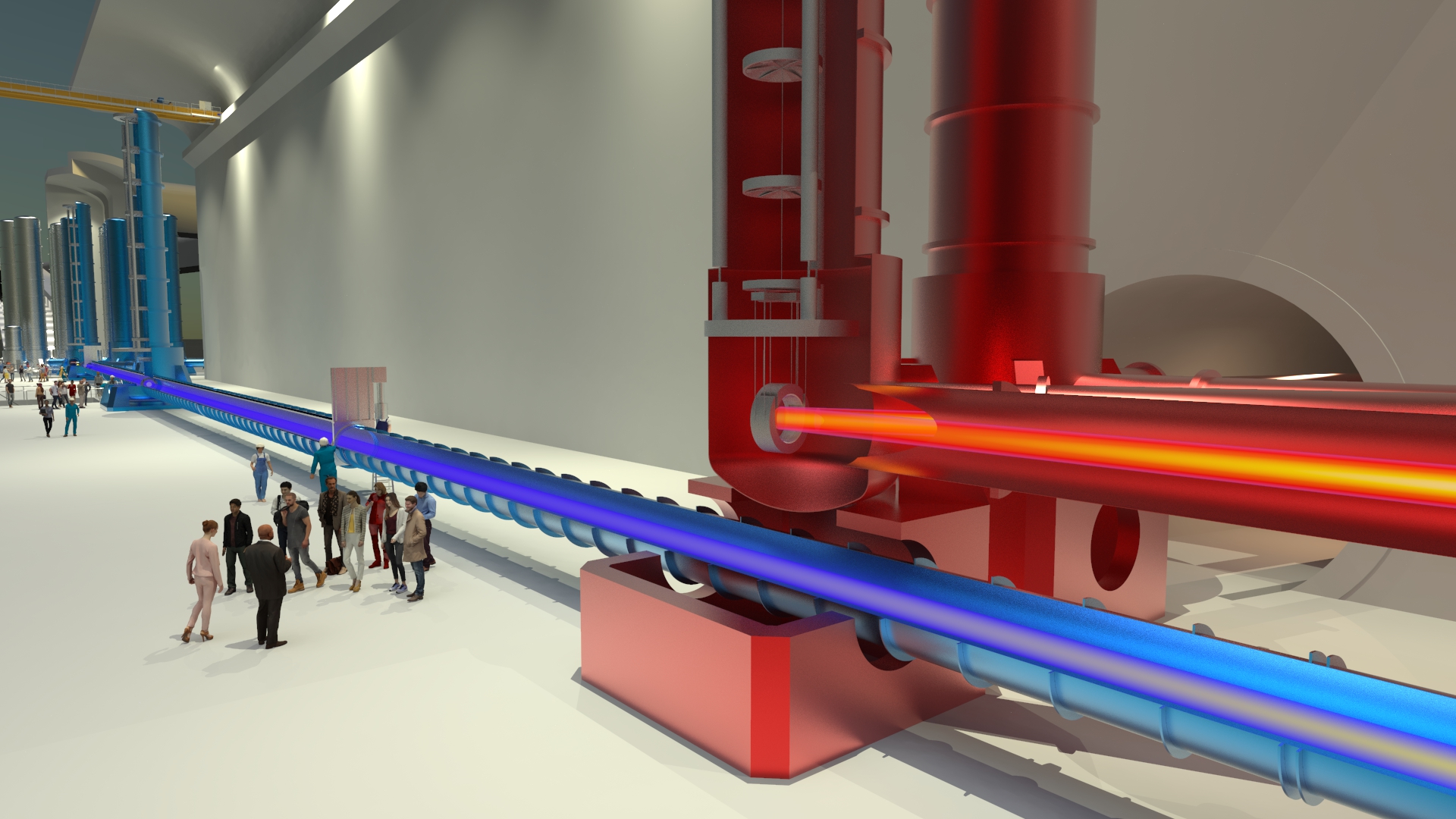

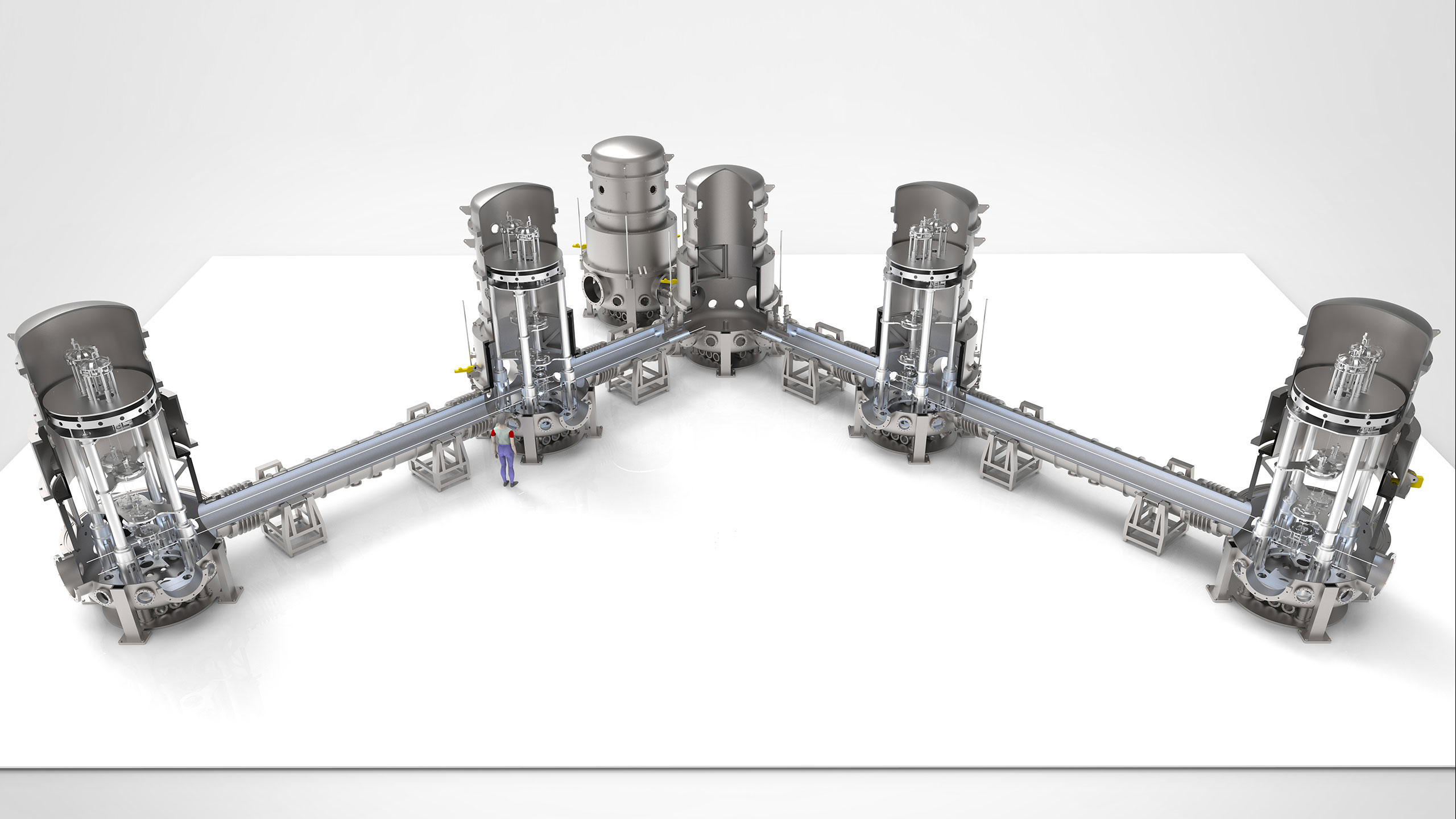

The future Einstein Telescope is a third-generation gravitational-wave observatory that relies on the measurement of minute relative length differences between the ten kilometre-scale long arms of a laser interferometer. An essential system herein is the huge UHV (about 10–10 mbar pressure) vacuum system: in the order of 130 kilometres of about 1 meter diameter UHV vacuum pipes to allow laser light beams to travel undisturbed between mirrors suspended from multiple coupled pendula to damp even the smallest external vibrations and housed in 10-20 meter high, 3-5 meter diameter UHV vacuum towers.

The installation of the UHV vacuum system for the Einstein Telescope will start around 2029 and be completed in 2032-2033. The estimated cost of the complete UHV vacuum system is 400-600 M€.

Present gravitational-wave observatories like LIGO (USA) and Virgo (Italy) use stainless steel (AISI304L) for their 3-4 kilometers long UHV vacuum tubes (3-4 mm wall thickness, 0.7-0.9 meter diameter) and their up to 12 meters high towers (10 mm wall thickness, few meters diameter). The vacuum tubes are welded from 10-20 meter long segments in situ with bellows to allow for (thermal) deformations during bake-out, with large vacuum valves to facilitate compartmentalized venting/access operations and with pumping stations typically every 500 meters. Near the vacuum towers, large cryotraps –to freeze out water vapor– are installed to improve the vacuum pressure in the long vacuum tubes to avoid disturbances of the laser beams. Prior to installation most components are baked-out at temperatures as high as 450oC for one week to reduce notably hydrogen and hydro-carbons contaminations while in-situ the systems can in principle be baked-out to reduce residual water at temperatures up to 150 oC for ten days (to avoid damaging Viton O-rings and pumps). These systems and notably the long vacuum tubes that have proven to operate reliably at 10-9 mbar pressure for extensive periods.

Relation to the Einstein Telescope

Innovation

A straightforward extrapolation of the LIGO and Virgo vacuum system would be very expensive because of the base material (stainless steel) as well as the underground installation costs.

The main challenge here is to reduce costs. We are thinking of several ways to accomplish this:

- Production of the UHV vacuum tube segments in a dedicated local production facility in or near the Einstein Telescope site. This will warrant overall operational performance and allow inevitable repair interventions.

- Use alternatives for the ‘classic’ stainless steel tubes. For example mild steel, nested tubes or corrugated thin-walled stainless steel vacuum tubes. This technology may already be available in industry (oil & gas, offshore, windmill, hyperloop, hydrogen fuel cells). Institutes like CERN could also contribute to solutions. And corrugated thin-walled stainless steel tubes are already used by the GEO600 project in Hannover. A major challenge for the nested tubes concept will be its robustness in view of a leak in the outer shell risking the disastrous collapse of the thin (stainless steel) inner lining.

- Reducing the costs of the UHV-vacuum related instrumentation (pumps, valves, bellows and diagnostic tools like residual gas analysers, all should operate with minimum vibration to maintain the Einstein Telescopes sensitivity).

Industrial relevance and further application fields

Not available

References

For further information and more details about this technology field, please check the following Einstein Telescope Design Reports.

E-TEST Conceptual Design Report:

Einstein Telescope Conceptual Design Report:

Vacuum: Pages 147-160

Contact to the Einstein Telescope ecosystem

Are you active in this field of technology? Do you have an innovative approach to meet the requirements for vacuum technologies? Then take note of our tenders, join our challenges or simply get in contact with us. Furthermore, you can take a look at the mapping displaying the ET-relevant cempetencies in the EMR-Region. If you would like to be part of this mapping, please contact the business development managers.

Business development contacts

Peter Gier

AGIT DE – p.gier@agit.de

Matthias Grosch

NMWP.NRW DE – matthias.grosch@nmwp.de

Michel Stassart

Skywin BE – michel.stassart@skywin.be

Annick Pierrard

ULiège BE – a.pierrard@uliege.be

Maxime Corvilain

POM Limburg BE – maxime.corvilain@pomlimburg.be

René Kessen

LIOF NL – rene.kessen@liof.nl

Scientific contacts

Patrick Werneke

Nikhef (NL) – p.werneke@nikhef.nl