Technological Challenge

The 10 km long arms may have a diameter up to 7m and will, most likely, be excavated by Tunnel Boring Machines (TBM). In order to facilitate a cost and time effective excavation and a precise geological documentation, the TBM drive should be equipped with innovative solutions for a real-time assessment:

– Geological conditions ahead of the tunnel face

– Tunnel face behavior

– Real time info on cutter wear

In addition, an innovative geological documentation methodology is needed. These innovative technologies should form the basis for a future TBM autopilot.

Relation to the Einstein Telescope

Relation to the Einstein Telescope

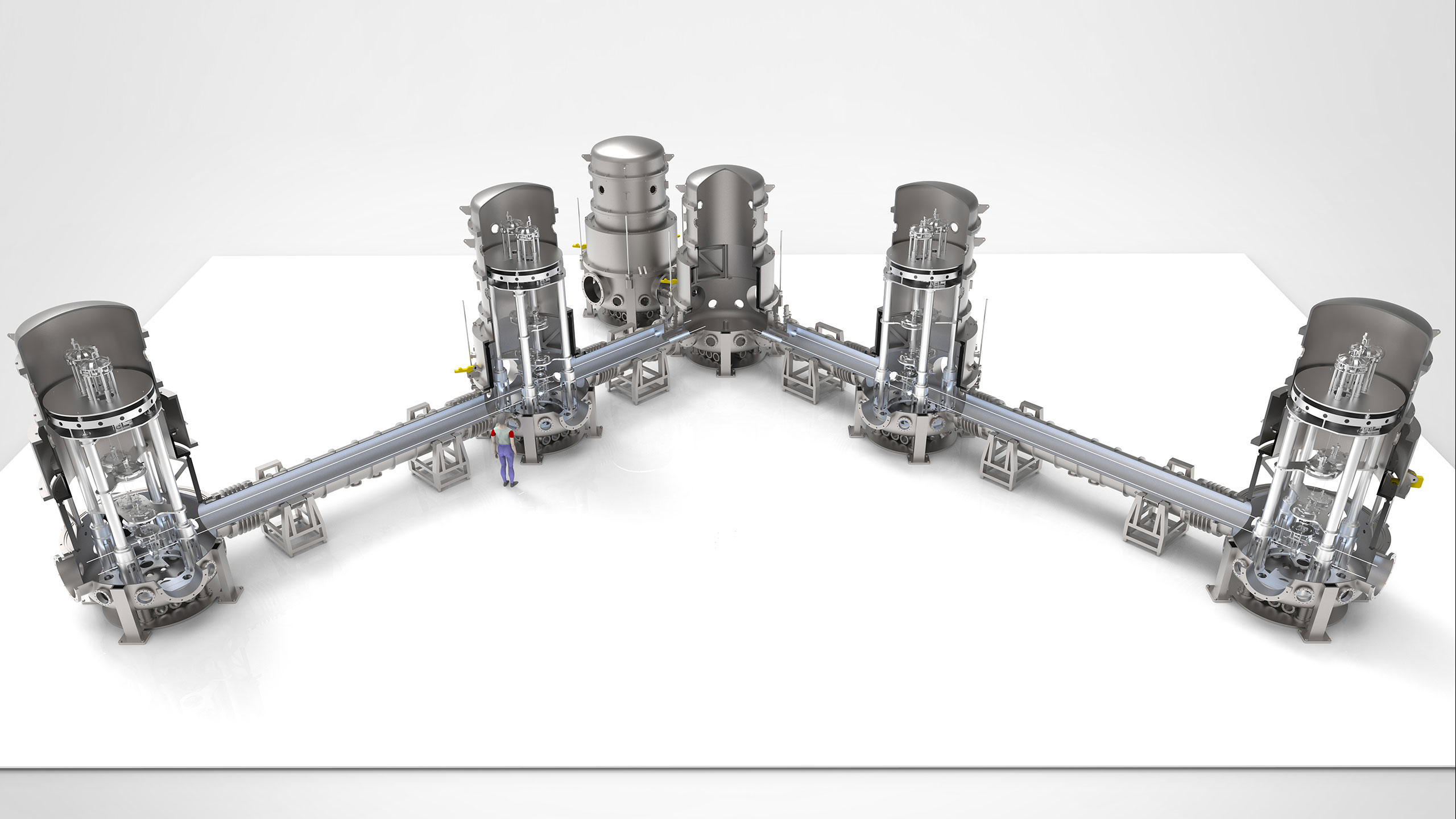

The construction of the Einstein Telescope (ET) will require the excavation of three 10km long tunnels at 300m of depth. The formation of the tunneling will be triangular with at each corner an additional cavern, which will host the spectrometers. The envisioned spectrometer will allow the Einstein Telescope to measure gravitational waves in an unprecedented resolution.

To observe gravitational waves, the Einstein Telescope has a design sensitivity of 22 decimal places. This means that it can detect differences in distance ten thousand times smaller than the size of the protons in an atomic nucleus. To achieve that incredible accuracy, the observatory bounces laser beams up and down long tunnels. An ultra-high vacuum and specially designed dampers filter out disruptive vibrations from the immediate environment. To further reduce interference from earthly vibrations, the Einstein Telescope will be constructed in 10km long underground tunnels at a depth of 300m.

Innovation

Topic 1: Assessment of Geology

The assessment of geological conditions ahead of the tunnel phase requires a real-time assessment of geological structures combined with geological modelling methods. The assessment could be an combination of photogrammetric methods, automated structural analysis tools, existing or newly developed geological modelling tools as well as geophysical methods. A precise geological real time documentation is a key component in the short-term decision making process and serves as an important basis for long-term maintenance.

Topic 2: Grain size distribution

A key indicator for assessing the tunnel face behavior is the grain size distribution of the excavated material on the conveyer belt. In blocky ground conditions, block size increase and negatively affect the cutter wear. Consequently, both rpm and thrust force must be regulated by the TBM personnel to minimize cutter wear and optimize the TBM performance. Innovative solution might be based on cameras in combination with AF for an automatic recognition on the grain size distribution.

Topic 3: Cutting tools wear

Cutter wear monitoring is a key aspect in the optimization of the TBM performance. Early indication of cutter wear allows an optimized maintenance schedule. Innovative solutions are needed to quantify cutter wear of each individual cutter in an automated fashion.

Industrial relevance and further application fields

The demand for underground construction is increasing worldwide. The technologic advancements could impact efficiency for future tunnel constructions, which would benefit durations and cost of future infrastructure projects. Tunneling technologies and the construction of tunnels can also create other economic value streams by extracting knowledge, heath or difficult to access materials from the surface.

Geothermal energy

The topic of geothermal energy includes both the geoscientific investigation of the thermal situation and the engineering use of geothermal energy.

Geothermal energy is the heat stored in the accessible part of the earth’s crust and is one of the renewable energies. Geothermal energy can be used for heating, cooling, generating electricity, or combined heat and power generation.

To use geothermal energy, the inner shells of the tunnels can be equipped with collectors and a circulating medium, and in this way, function as heat exchangers. This is also possible in tunnels constructed by mechanical excavation and lined with segmental linings. The heat obtained can be used for heating, cooling, and power supply of the underground facilities.

The development of the collectors and the so-called energy segmental linings has rarely been tested so far, and the tunnels to be constructed here can be used on the one hand as a test field and on the other hand as direct consumers of the recovered energy. With the tunnels located up to 300 m below ground, a very high degree of utilization of the geothermal plants can be expected.

Geophysics

The tunnels open up areas of the earth’s crust that seismic surveys from the surface can rarely detect. The excavations and tunnels can be used to explore the Liège/Ardennes/Eifel region more closely seismologically and to open up new possibilities for earthquake research in a still active earthquake region.

This is possible through boreholes driven from the tunnel perpendicular to the tunnel axis. By arranging tunnels parallel to each other, research and developments in the field of georadar can also be undertaken and tested.

Reuse of excavated ground for construction material

The potential of the excavated masses in terms of recycling is very interesting. The excavated masses are extracted at a depth of 300m in undisturbed rock and can be used as aggregates for concrete, road construction, dam, and dike construction. This means they can be used for land reclamation and coastal protection in the Netherlands and Belgium. Landfilling of material, which worsens the balance, can be reduced to a minimum.

References

For further information and more details about this technology field, please check the following Einstein Telescope Design Reports.

E-TEST Conceptual Design Report:

Einstein Telescope Conceptual Design Report:

Tunnels: Pages 177-191

Contact to the Einstein Telescope ecosystem

Are you active in this field of technology? Do you have an innovative approach to meet the requirements for tunneling? Then take note of our tenders, join our challenges or simply get in contact with us. Furthermore, you can take a look at the mapping displaying the ET-relevant cempetencies in the EMR-Region. If you would like to be part of this mappink, please contact the business development managers.

Business development contacts

Peter Gier

AGIT DE – p.gier@agit.de

Matthias Grosch

NMWP.NRW DE – matthias.grosch@nmwp.de

Michel Stassart

Skywin BE – michel.stassart@skywin.be

Annick Pierrard

ULiège BE – a.pierrard@uliege.be

Maxime Corvilain

POM Limburg BE – maxime.corvilain@pomlimburg.be

René Kessen

LIOF NL – rene.kessen@liof.nl

Scientific contacts

Raul Fuentes

RWTH Aachen DE – raul.fuentes@gut.rwth-aachen.de