Technological Challenge

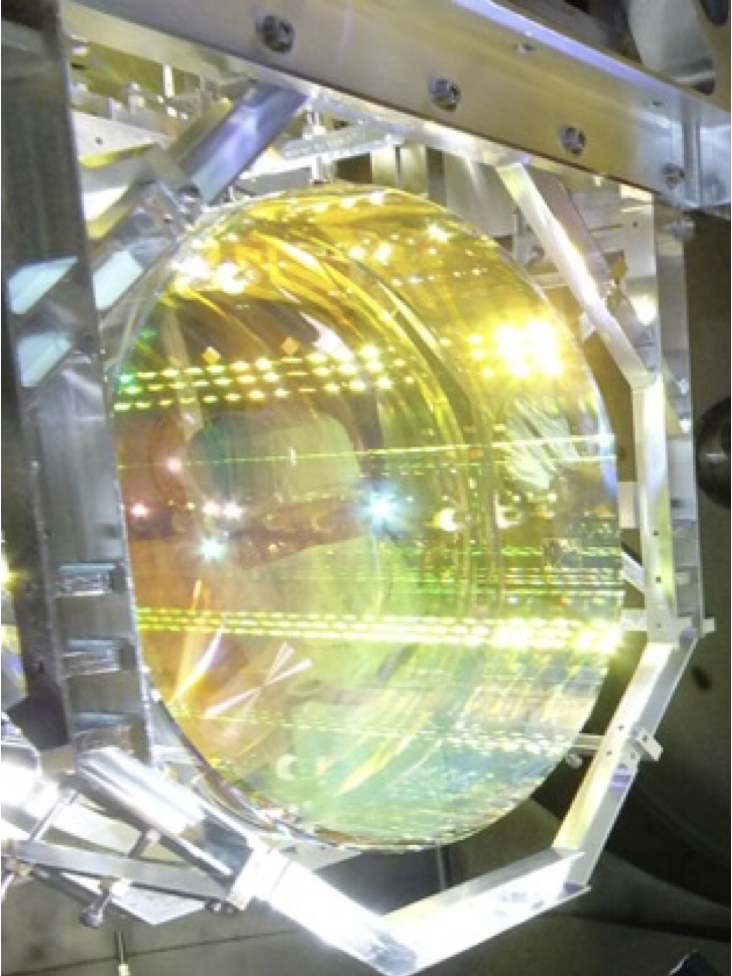

Highly-reflective coatings are obtained by stacking of many layers, usually using two materials with different refractive index n

- optical layer thickness: quarter of a wavelength (= higher n → thinner layer)

Example: amorphous SiO2 (n=1.45) and Ta2O5 (n=2.05) - ~38 layers needed for highly reflective ETMs of R = 99.9995%

- light intensity reduces with every layer pair

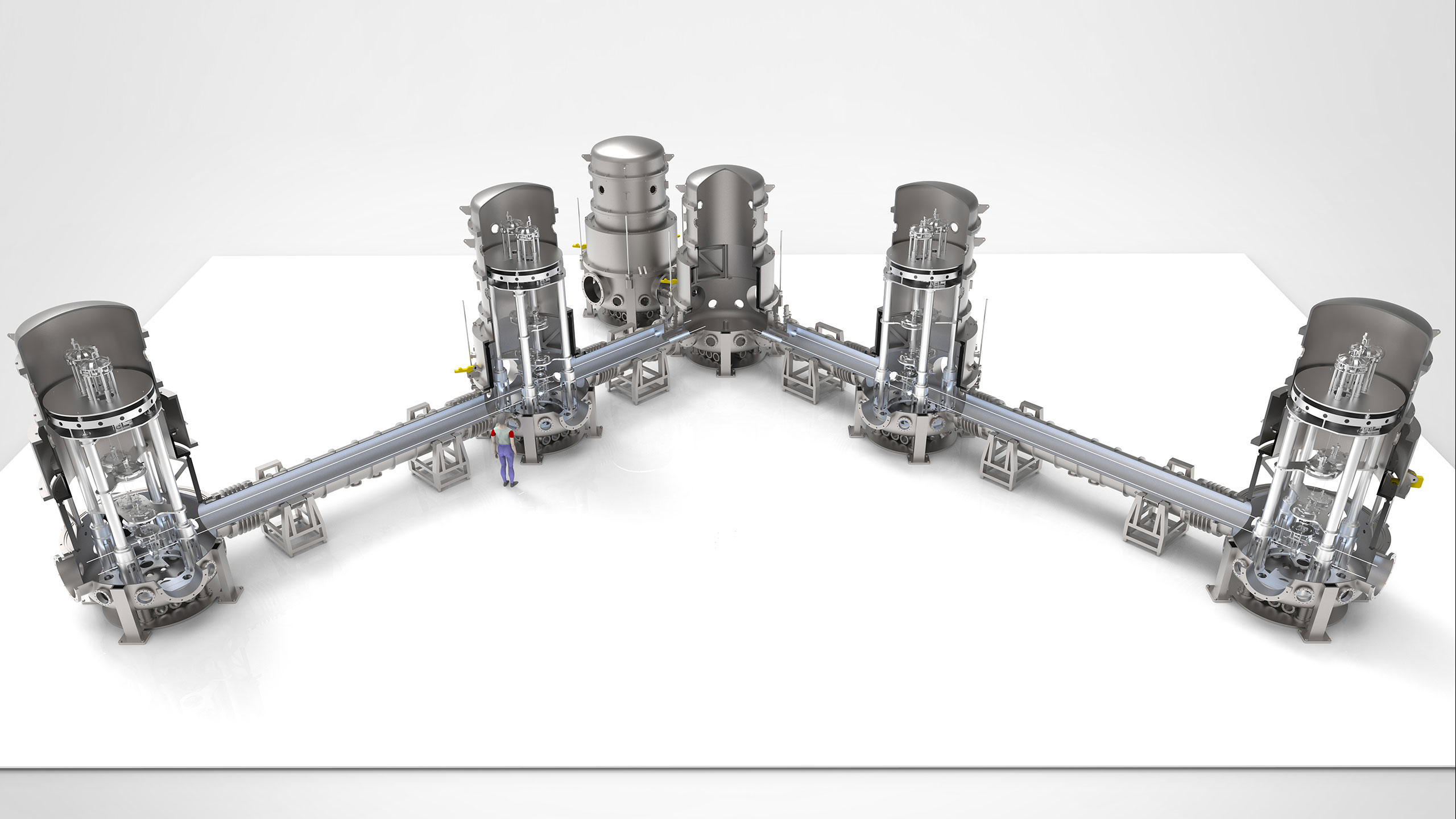

Relation to the Einstein Telescope

Relation to the Einstein Telescope

To improve the telescope performance, two approaches are followed in parallel for the mirrors. First, the diameter (d) of the mirror bodies is increased since noise scales with. The second path is to significantly improve the CTN by lowering the temperature of operation as well as to significantly lower (~ factor of 10) the mechanical losses of the coatings.

Innovation

ET-HF:

- Same wavelength, substrate material and temperature as LIGO and Virgo detectors

- Challenge: Upscaling coating diameter by almost a factor of two (bubble- and defect-free)

ET-LF:

Active research areas within extended EMR region: nanolayers, multi-material coatings and crystalline coatings

Industrial relevance and further application fields

Proposals for joint ET-relevant R&D activities / new business applications: To be filled in on the base of the companies’ proposals

References

For further information and more details about this technology field, please check the following Einstein Telescope Design Reports.

E-TEST Conceptual Design Report:

Coatings: Pages 57-58

Einstein Telescope Conceptual Design Report:

Coatings: Pages 101-108

Contact to the Einstein Telescope ecosystem

Are you active in this field of technology? Do you have an innovative approach to meet the requirements for mirrors coating? Then take note of our tenders, join our challenges or simply get in contact with us. Furthermore, you can take a look at the mapping displaying the ET-relevant cempetencies in the EMR-Region. If you would like to be part of this mappink, please contact the business development managers.

Business development contacts

Peter Gier

AGIT DE – p.gier@agit.de

Matthias Grosch

NMWP.NRW DE – matthias.grosch@nmwp.de

Michel Stassart

Skywin BE – michel.stassart@skywin.be

Annick Pierrard

ULiège BE – a.pierrard@uliege.be

Maxime Corvilain

POM Limburg BE – maxime.corvilain@pomlimburg.be

René Kessen

LIOF NL – rene.kessen@liof.nl

Scientific contacts

Jean-Pierre Locquet

KU Leuven BE – jeanpierre.locquet@kuleuven.be