Technological Challenge

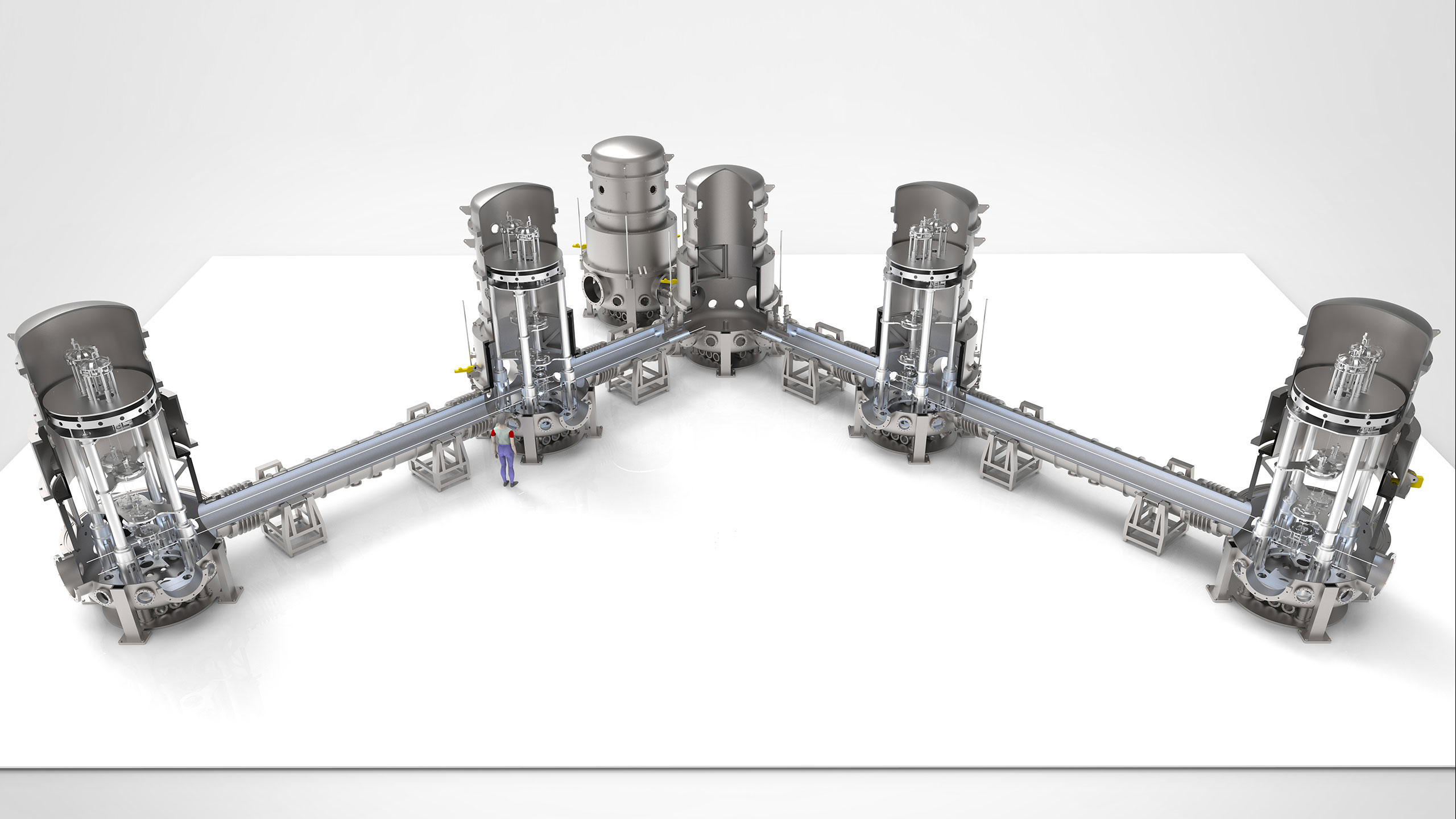

The Einstein Telescope (ET) will feature three detectors with core optics operating at 10K. For this reason, 12 large volume (10m3) UHV cryostats will be realized, each of them surrounding a cryogenic payload consisting of a mirror (200kg mass, 500-mm diameter monocrystalline silicon substrate) and its suspension and steering mechanics.

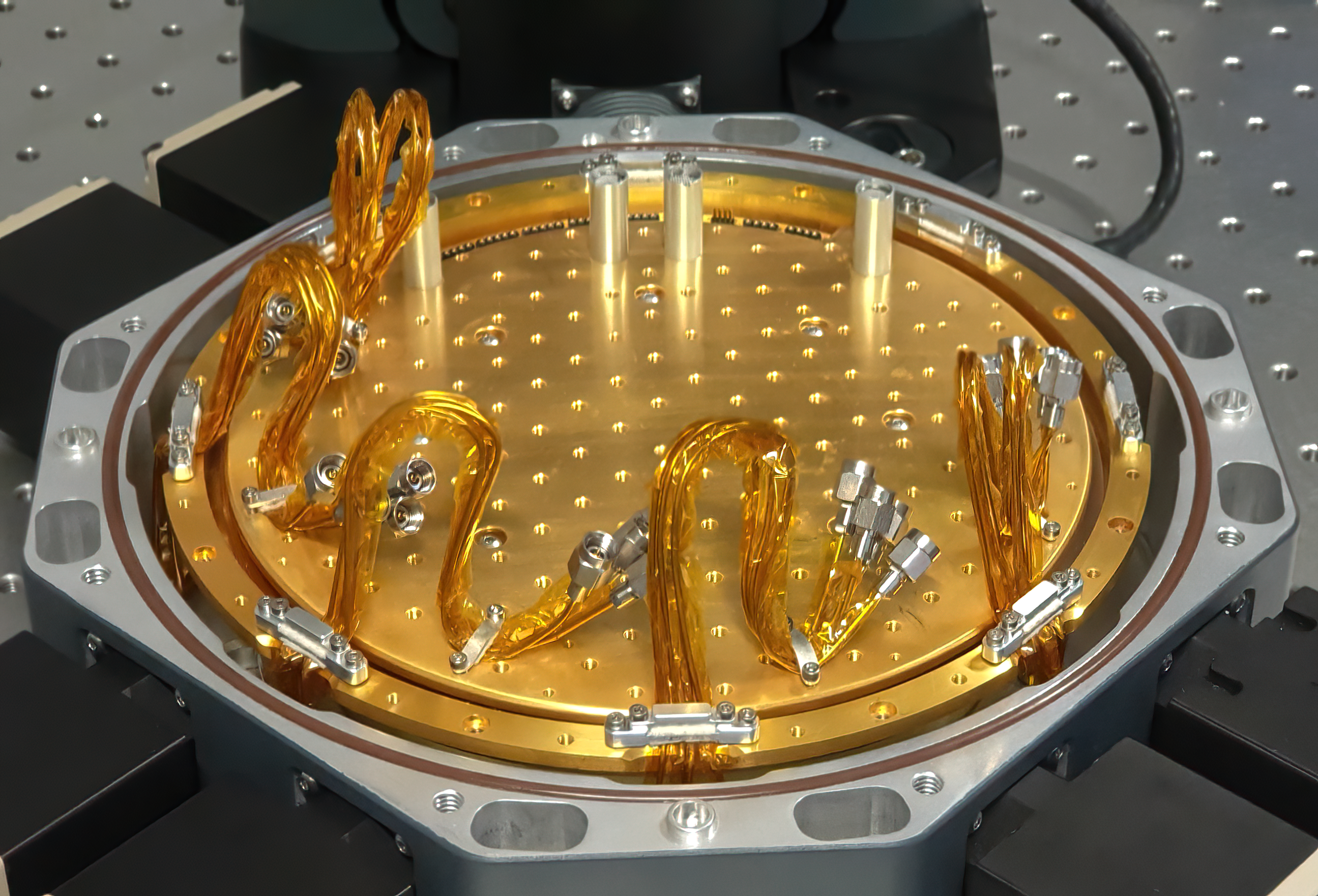

After the initial cooldown, the operating temperature of the payload must be maintained only via radiation and conduction through very low stiffness thermal straps (heat links), to ensure that the telescope performance is not affected by vibrations from the cryogenic plant. In this scenario, availability of ultralow noise cryocoolers and active vibration isolators compatible with the UHV low temperature environment is essential.

The low temperature mirrors will be suspended by means of monocrystalline silicon fibers 1-m long and a few mm thick. Manufacturing technology of such those fibers is at very early stage and requires a strong R&D program and support from industry to reach the readiness needed for the success of the project.

Relation to the Einstein Telescope

Relation to the Einstein Telescope

Observation of gravitational waves is only possible if the acceleration of the mirrors is reduced by billions of times compared to the quietest research laboratories.

Though this outstanding figures have been achieved at room temperature in the current detectors, cryogenic operation brings in new challenges and the control/management of introduced vibrations is crucial. The foreseen strategy for the refrigeration of the mirrors is to combine ultra low vibration cryocoolers, active vibration isolation of the cryocooler cold head and low stiffness heat links to connect it to the cryogenic payload.

Single-crystal silicon fibers have been chosen for the ET core optics suspension since this material provides the best performance in terms of high efficiency heat extraction from the mirror at 10K and the lowest possible mechanical damping, a property that is crucial to reach the scientific goals of the project.

Innovation

- sapphire fibers used in KAGRA are not ideal for ET since the thermal conductivity of the material drops significantly below 20K. Silicon is better material in terms of thermal properties and mechanical damping figures. Manufacturing is at the moment the main challenge towards a practical implementation.

- cryogenic plant induced noise figures achieved in KAGRA are not compatible with the Einstein Telescope requirements; quieter cryocoolers and better performing vibration isolation for the heat links are needed.

- the ET cryogenic payload will add up to a few hundred kg mass (nearly a factor of 10 larger than in KAGRA) to be cooled down to 10K. Methods and technologies (high emissivity coatings, high efficiency radiation heat exchangers, etc.) for minimizing the cooldown time are of paramount importance for ensuring the telescope a high duty cycle.

- standard super-insulation (MLI or similar) is not compatible with the mirror environment due to contamination requirements. Alternative design solution must be explored.

- ice thin layer formation (nanometer level) on the mirror surface is expected to degrade the telescope performance. Methods and strategies for minimizing the ice formation and for periodical regeneration of the surface must be developed.

- interest is growing around an alternative solution, more projected towards the future, in which the cooling power is provided by means of superfluid He. R&D activities are now starting in this direction.

Industrial relevance and further application fields

ET represents the most extreme test bed for advanced ultra low noise cryogenics.

ET-proof innovation in this field can be transferred, among others, to the realm of quantum computers in which excess vibrations from the cooling system can cause decoherence of qubits and disrupt ongoing processes.

On the other side, the development of manufacturing methods of high quality silicon monocrystalline fibers can be attractive for fiber-optic communication at THz wavelengths where silicon has been identified as the ideal core material for its unique low attenuation properties.

References

For further information and more details about this technology field, please check the following Einstein Telescope Design Reports.

E-TEST Conceptual Design Report:

Cryogenics: Pages 42-54

Einstein Telescope Conceptual Design Report:

Cryogenics: Pages 144-147

Contact to the Einstein Telescope ecosystem

Are you active in this field of technology? Do you have an innovative approach to meet the requirements for cryogenics? Then take note of our tenders, join our challenges or simply get in contact with us. Furthermore, you can take a look at the mapping displaying the ET-relevant cempetencies in the EMR-Region. If you would like to be part of this mappink, please contact the business development managers.

Business development contacts

Peter Gier

AGIT DE – p.gier@agit.de

Matthias Grosch

NMWP.NRW DE – matthias.grosch@nmwp.de

Michel Stassart

Skywin BE – michel.stassart@skywin.be

Annick Pierrard

ULiège BE – a.pierrard@uliege.be

Maxime Corvilain

POM Limburg BE – maxime.corvilain@pomlimburg.be

René Kessen

LIOF NL – rene.kessen@liof.nl

Scientific contacts

Stefan Hild

Maastricht University NL – stefan.hild@maastrichtuniversity.nl

Cédric Lenaerts

Centre Spatial de Liège – CSL ULiège BE – cedric.lenaerts@uliege.be